Components of the Wii U Pro Controller

Background

This article was written as part of a project to determine the digital life cycle of the Wii U Pro controller for a class called Digital Trash at RU-C, in which we investigated how the technology we use is often broken down and thrown away.

The Wii U Pro controller was one of the first controllers from Nintendo that was considered by the company to be a bit more “professional.” Its style is more similar to that of the PS3 and Xbox 360 controllers, rather than Nintendo’s previous controller iteration, the Wii Remote. While the Pro Controller did not come with the Wii U and the standard Wii Remotes could still be used on the Wii U, it was a welcome change to players who wanted to play some of the more “hardcore” games that were on the Wii U at the time. Since the standard for Wii controllers was to connect through Bluetooth, it made connecting and using the Pro controller with other devices easy.

Breaking it Down

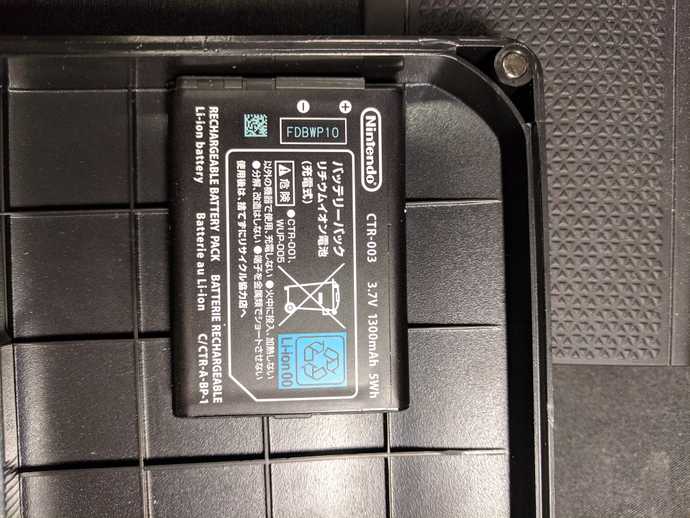

Overall, the controller was easy to take apart and did not have too many components. First to come out was the 1300mAh battery, which is interestingly the same battery used in the 3DS and 2DS. It was marked with both “CTR-001” and “WUP-005” which are Nintendo’s internal codes for the 3DS and Wii U respectively, which tipped me off that it might be the same battery. While this battery gets only about 15 hours of gameplay on the 3DS, it gives the Pro Controller over 80 hours of battery life on a single charge.

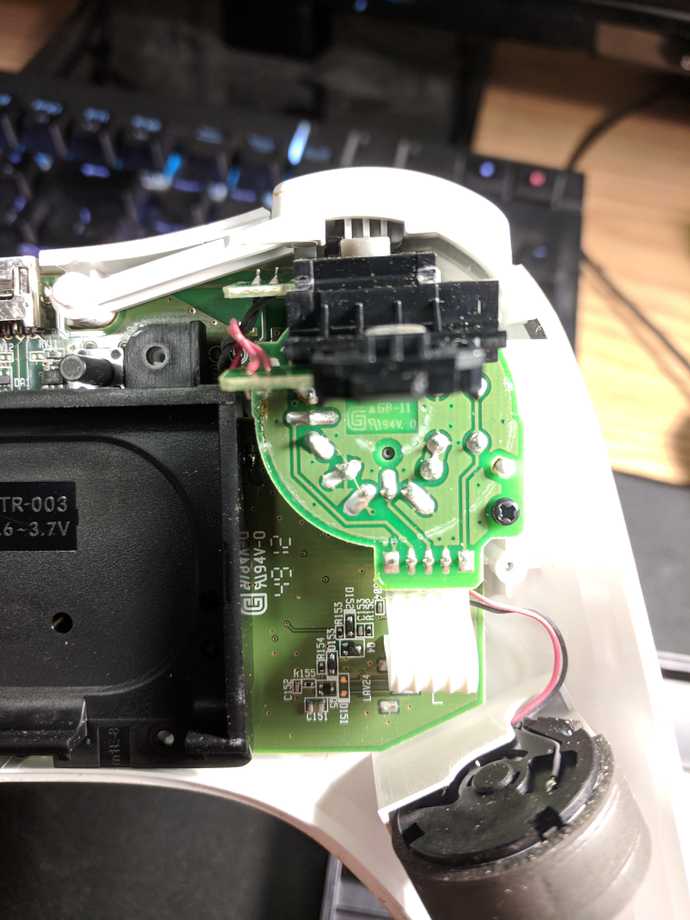

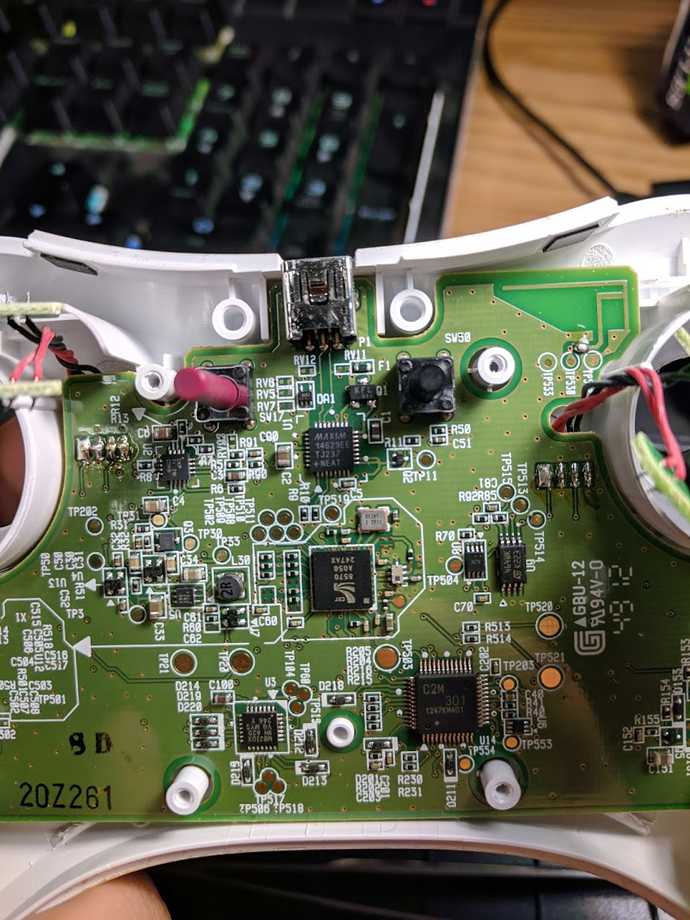

After taking the battery cover off, we find that the shoulder buttons (ZR, ZL, L, and R) as well as the joysticks on each side have their own small board connected to the main board by a large ribbon cable. Both of the joystick circuit boards and the main motherboard seem to be manufactured by a company called Mitsumi, which I found also manufactured the boards for the Gamecube controller when I looked inside of that. The Rumble Motor was also attached to the back facing side of the board, and located only in the cavity of the left grip. The rumble motors in other controllers I have seen have been more centered, so it is interesting to see one located mainly on one side of the controller. I would have never noticed if I had not opened it up though, so there is something good to be said about the effectiveness of it.

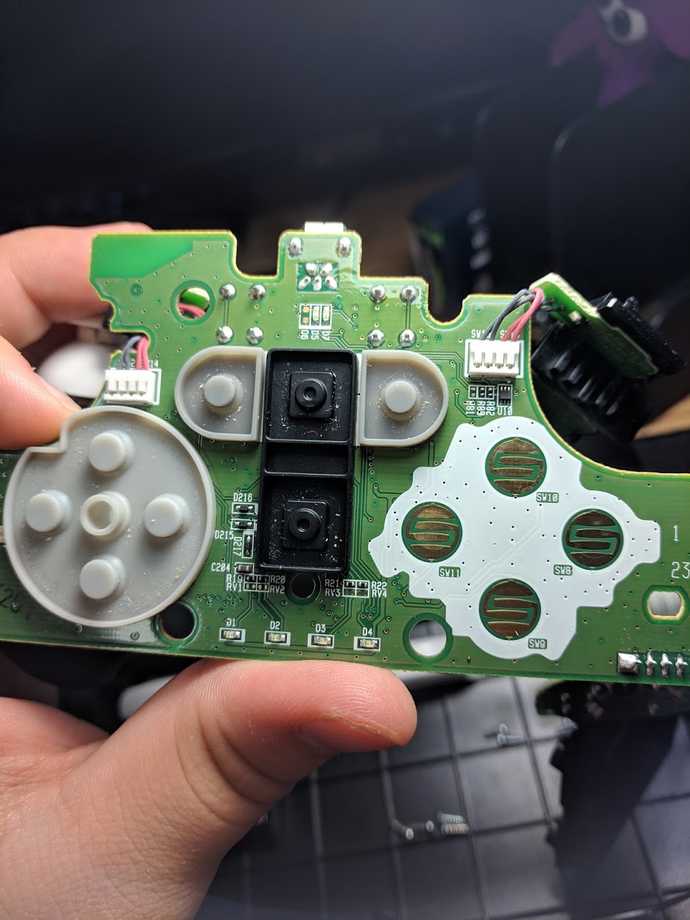

On the other side of the board (front facing) we find mostly silicone pads for the buttons. Two large ones on either side for the D-Pad and ABXY buttons, and 4 smaller ones for the central buttons (plus, minus, home, and power). All of the buttons themselves are made from hard plastic, and seem to have the letters as a separate color of plastic in the cylinder, so that they will not wear away as the button wears down.

The circuit boards contained in the controllers are usually either coated in epoxy resin, or some are made with phenolic resin. These boards all contain copper wires on the inside, to connect all of the components attached. After the board is completed and the copper circuits are in place, they are coated with tin-lead to prevent oxidation, nickel, and finally gold for conductivity. Since the circuit boards contain lead, they are considered to be hazardous when the boards are being printed, and thus fumes are released into the environment. It is expected that on lots of similar, less heavy-duty boards, they will become obsolete within 12-18 months.

There are many different types of vibration motors on the market for different kinds of devices, and the one inside the Wii U Pro controller is different from the one you would find in your phone for example. The vibration motor inside the Wii U Pro controller is called a Linear Resonant Actuator, and it does not have the precision of a vibration motor that would be in a smartphone. Its main capacity is to do one type of vibration. To achieve this, it uses a magnet core made of Neodymium magnets. The technical term is Neodymium Iron Boron, and its symbol is NdFeB. It is a type of ferrite magnet as well as a rare earth magnet. Often, similarly to the way copper is coated in circuit boards, the Neo Magnets are required to be coated in tin, nickel, or zinc to prevent oxidation. Since it is an incredibly powerful magnet, special care must be taken when handling them when the motor is being manufactured, so that the person handling it does not get injured due to magnetic attraction to something else. It was also noted in my research that NdFeB powder is very volatile in nature, and has been known to spontaneously combust.

Summary

Overall, the different types of metals that go into making the Wii U Pro controller and similar products have been known to be hazardous for one reason or another. Whether it be the fumes from lead being released into the environment after being used to coat copper wires, or the ability for certain forms of the material to ignite spontaneously, there is no doubt that after the controller has reached the end of its life, it will need to be disposed of properly. Some legislations in Europe require companies to provide a solution to toxic materials at the end of a product's life; the companies are required to buy back the materials and render them safe to recycle into the environment, as well as to properly dispose of waste that comes from this process. This is good because it forces the companies to provide solutions for problems they caused, or else lose more money. In turn, it also drives companies to research more eco-friendly alternatives to the materials they already use. In a market where planned obsolescence is everywhere, this could be a good solution to keep companies producing longer lasting devices, and put less toxic waste into the environment.